For those of you who already have kilns with electronic (digital) controllers, you know how nice they are to use. With a few presses of the keypad, you can execute pre-programmed cone firings or elaborate ramp-hold firing sequences. Electronic controllers help you bring consistency and repeatability to your firings. Once you use one, you begin to wonder how you got along without it. (As I like to say, "There's no going back.") Not to dismiss your trusty KilnSitter, but if you have a perfectly good kiln with a KilnSitter (or just switches), you may have wondered if you can upgrade your kiln with an electronic controller. The answer is ,"Yes, you can" and it's easy to do too.

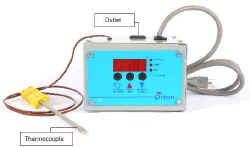

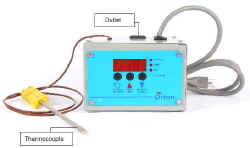

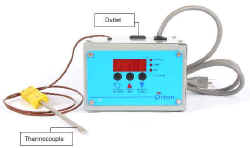

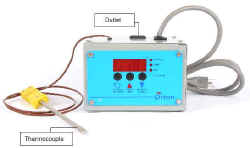

Orton Ceramics makes electronic kiln controllers (used on Paragon kilns), and they also make controller kits to upgrade existing kilns. There are two main types, which we'll review here, plus a lower cost variation for small/test kilns.

IN ITS SIMPLEST FORM:

You simply mount the controller on the wall near your kiln and insert the tip of the controller's thermocouple (temperature sensor) into the interior of the kiln. (You will have to identify a good location to do this, and will have to drill a small hole through your kiln brick.) Next, plug your kiln into the controller, and plug the controller into the electrical receptacle. That's it. It's installed!

SO HOW DOES IT WORK?

To run the kiln, you put a cone in the KilnSitter and latch it, just like you have in the past, only this time use a cone that is several cones higher than your desired firing. (The idea here is that the cone will never bend and trip the KilnSitter, and subsequently turn off the kiln. You just want the KilnSitter to be active, so electrical power can flow through it, so the elements will heat.) Now just program the electronic controller and press Start.

The thermocouple will sense the kiln's temperature, and when needed, will allow electricity to flow to the kiln. When the kiln has reached the appropriate temperature, the controller will turn off the electrical power and the elements will quit heating. This process will continue, with the kiln cycling on and off continuously until the end of the firing. What make this such a nice solution is that you leave your KilnSitter in place. No disassembly needed.